Raw Material SMC-BMC

BMC (Bulk Moulding Compound )

BMC (Bulk Moulding Compund) is a ready-to-use injection moulding compound containing polyester glass fibre, mineral fillings, pigments and a variety fillings. It can also be produced in desired colors. Some examples of various usage areas of BMC are electrical devices, automotive industry and engine parts due to its heat, solidity, mechanical and electrical properties.

| Characteristics | Test Methods | Unite | Electricity Applications |

Automotive (Injection) |

House Applications |

| General applications (enclosures, armatures) | Headlight housing, resistant for temperature, high quality surface coating | House appliances | |||

| Code | TNE - 109 | ||||

| Moulding Temperature | °C | 140 - 160 | 150-170 | 140 - 160 | |

| Density | ISO 1183 | g/cm3 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 |

| Absorption | ISO 62 - 1 | mg | <50 | >40 | <50 |

| Flexural Strength | ISO 14125 | MPa | 80< | 90< | 70< |

| Tensile Strength | ISO 527 - 4 | mpA | - | - | - |

| Impact Strenght | DIN EB ISO 179 | Kj/m2 | 20< | 20< | 20< |

| Shrinkage | ISO 1842 | % | 0,15 ± 0,05 | 0,05 ± 0,03 | 0,15 ± 0,05 |

| Flammability | UL 94 | HB | HB | HB | |

| Hardness | EN 59 ASTM - D 2583 - 95 | BARKOL Barcol | 70< | 70< | 70< |

| Flowing | 11< | 3< | 11< | ||

| Surface Resistance | DIN 53482 | ? | 10 E 11 | 11 E 11 | 12 E 11 |

| Glassfiber content | % | 14 | 14 | 14 |

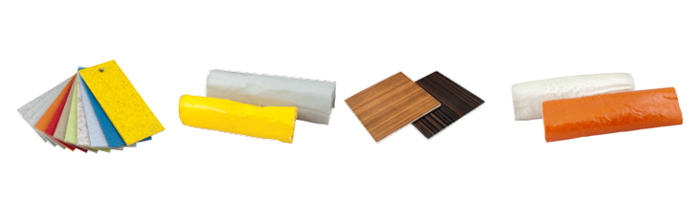

SMC (Sheet Moulding Compound )

SMC (Sheet Moulding Compound) is composed of polyester, glass fibres, mineral fillings, pigments and various additives. It can also be produced in desired colors. Some examples of various usage areas of SMC are construction, automotive and electrical industries.

| Characteristics | Test Methods | Unit | Electrical Applications | Electrical Applications | Siding | House Applications | Automotive | Automotive | Peysage Products | Highway Applications |

| Switches, contactors | Voltaic cells | Service Appliances | Bumpers | External parts | Benches, Stadium seats | Pedestrian gates | ||||

| Code |

FRS 22 TN 500 UP-GF-28 |

|||||||||

| Mouding Temperature | °C | 150 - 170 | 140 - 160 | 140 - 160 | 140 - 160 | 140 - 160 | 140 - 160 | 140 - 160 | 140 - 160 | |

| Density | ISO 1183 | g/cm3 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 | 1,8 - 2 |

| Absorption | ISO 62 - 1 | mg | <40 | <50 | <50 | <50 | <40 | <40 | <50 | <40 |

| Flexural Strength | ISO 14125 | Mpa | 120< | 140< | 180< | 160< | 360< | 130< | 160< | 160< |

| Tensile Strength | ISO 527 - 4 | MPa | 90< | 80< | - | - | 180< | - | - | - |

| Shrinkage | ISO 1842 | % | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 | 0,15 ± 0,05 |

| Flammability | UL 94 | V0 | V0 | - | - | - | - | - | - | |

| Hardness |

EN 59 ASTM - D 2583-95 |

BARKOL | 70< | 70< | 70< | 70< | 70< | 70< | 70< | 70< |

| Flowing | 11< | 11< | 11< | 11< | 11< | 11< | 11< | 11< | 11< | |

| Surface Resistance | DIN 53482 | ? | 10 E 11 | 10 E 11 | 10 E 11 | 10 E 11 | 10 E 11 | 10 E 11 | 10 E 11 | 10 E 11 |

| Glassfiber Content | % | 21 | 28 | 22 | 25 | 40 | 30 | 28 | 30 |

Product Catalog